Common mailroom machine codes and maintenance checks to keep you running

If your franking machine has stopped working, or you've suddenly got an error code you've not seen before - don't worry - the answer could be a simple one. Just have a look through the handy FAQ section here, and browse though the error codes. If you can't find the problem, or you need an maintenance visit, we are here to help and have engineers based all over the UK to ensure a speedy visit and get you up and running before long.

We're here to help with your franking machine problems ... just call 0118 982 0988

Important changes to franking machines

Royal Mail requires all franking machines to be upgraded to MailMark franking.

| Abbreviation | Service | Description |

|---|---|---|

| SpDel | Special Delivery | Tracked next day mail requiring a signature on delivery and delivered by a set time |

| RoW Z2 Air | RoW Z2 Air mail | Australasia |

| RoW Z1 Air | RoW Z1 Air mail | N. America, S. America, Africa, Asia |

| RM Signed for | Royal Mail Signed for | Tracked mail requiring a signature on delivery |

| Rest of World Surf | International Surface mail | International mail not using planes (Boat, Train and road only) |

| PC 200/300/400/500 | Plus compensation | Compensation amount if lost or damaged |

| LC-1000 / 2500 / 5000 / 7500 / 10000 | Consequential Loss | The amount Royal Mail will pay if you are charged for late delivery (time sensitive documents i.e Legal and Tax documents) |

| Intl Letter / Small Packet / Printed Paper / Global Value / Global Economy | International postage options | Global Value and Global Economy are used for any international Parcel Force services. You will need to register with Parcel Force to use these services |

| Europe non-EU Air | Europe non-EU Air mail | Any Country within Europe but not in the EU |

| Europe EU Air | Europe EU Air mail | Any Country within Europe and the EU (i.e France, Germany) |

| 9AM / 1PM | Before 9AM / 1PM delivery | The latest the item will be delivered by |

| 50/500/1000/2500 | Compensation amounts | The amount of compensation (in pounds) that Royal Mail will pay if the item is lost or damaged |

| +SG | Saturday Guaranteed | Guaranteed Saturday delivery for Special Delivery items |

Maintenance to keep your Folder Inserter working without error

Daily

- Check the system functions

- Keep the system in proper condition by removing dust, paper remains etc.

- When dirty, clean the sealing table and rollers with a slightly wetted cloth, soaked in warm water.

Weekly

- When dirty or saturated, clean the brushes of the envelope sealing (see "cleaning or replacing moistening brushes" section)

- Clean rollers (see "clean the system" section).

Cleaning or Replacing Moistening Brushes

See “Filling the Sealing Liquid Reservoir” for the location of the brushes.

1. Open the system.

2. Lift the sealing liquid reservoir with the blue handles carefully out of the system.

3. Remove the three brushes.

4. Clean the brushes with a small amount of water.

If the brushes are worn, replace them with new ones.

5. Install the brushes.

6. Fill the tray with sealing liquid.

7. Make sure the brushes are moistened sufficiently.

8. Replace the liquid reservoir.

9. Close the system.

Clean the System

1. Open the system.

2. Clean the rollers. Use a cleaning product recommended by your authorized distributor and apply it with a lint-free cloth. Wipe each rubber roller while turning it manually.

3. Clean the casing of the system with a damp cloth and a slightly soapy solution.

Fault finding

Error Messages

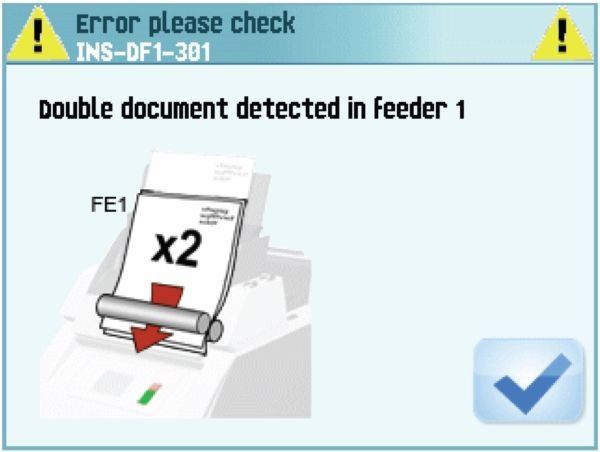

When an error occurs the touch screen shows a menu showing the following information:

• An indication of the area in which the error occurred.

• An error description.

• A suggested solution.

Special Errors

- Technical errors.

The touch screen shows a message. The error cannot be solved by operating personnel and assistance of the service support is needed.

Warning Screen

When a cover is opened, the touch screen shows a warning screen with the message “Cover open” and a suggested solution “Close cover”.

Clearing Stoppages

Stoppages can occur in the following areas:

• Document feeders.

• Document path.

• BRE feeder.

• Envelope feeder.

Document Feeders

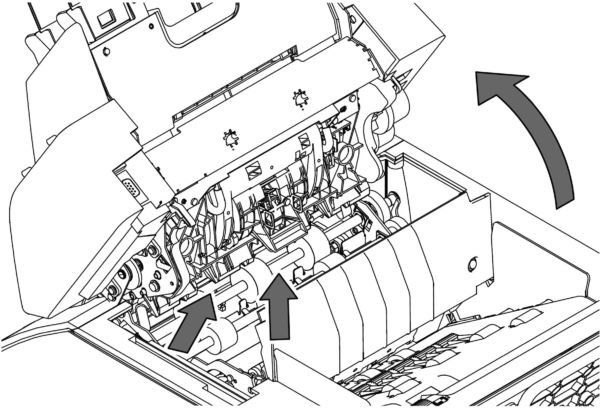

When a stoppage occurs in the document feeders, remove the documents as follows:

1. Pull the feeder block forward (see figure).

2. If necessary lift the feeder block out of the system.

3. Remove the documents from the bottom of the feeders.

4. Return the feeder block into the system.

Document Path

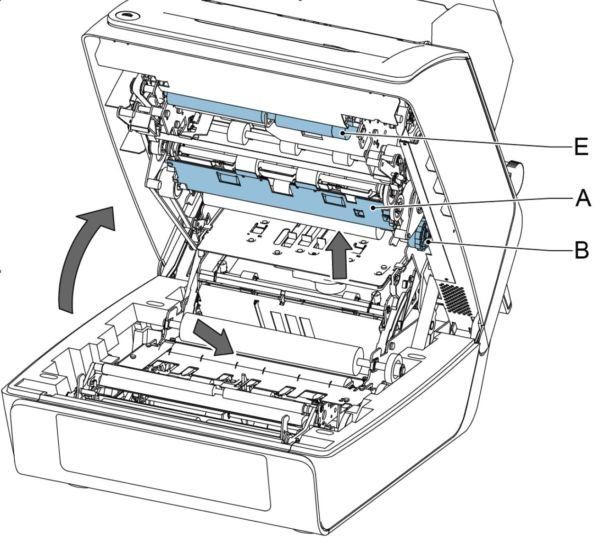

When a stoppage occurs somewhere in the document path, remove the documents as follows:

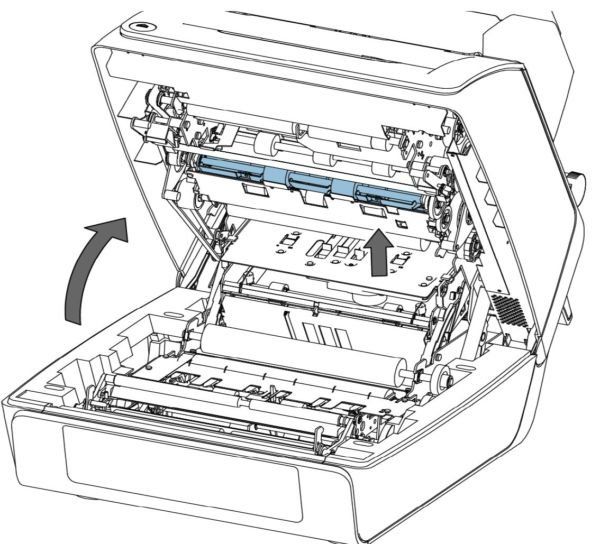

1. Press the button to open the system.

2. If necessary lift flap A, or rotate B or roller E to transport the document.

3. Remove the documents.

4. Close the system.

Feeder 3

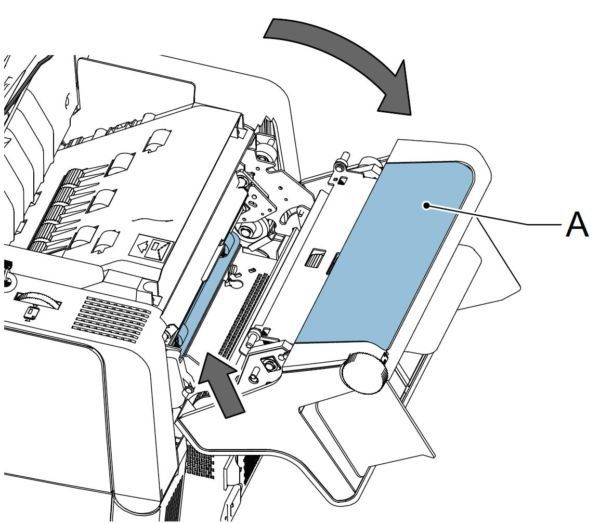

When a stoppage occurs in feeder 3, remove the document or envelope as follows:

1. Press flap A of feeder 3 and rotate the feeder downward.

2. Remove the document or envelope.

3. Close the feeder.

Envelope Hopper

When a stoppage occurs in the envelope hopper, remove the envelopes as follows:

1. Press the button to open the system.

2. Remove the envelope: If this is not possible, try to remove it from the top of the hopper.

1. Close the system.

2. Remove the envelope stack and remove the envelope.

Operator Troubleshooting

To solve problems:

1. Write down the error.

2. Consult the troubleshooting tables in sections 6.3.1 up to 6.3.5 to solve the problem.

3. Switch the system off and on again, to verify system operation.

4. When the error still occurs contact your service organisation.

Note

When contacting IMS you will also be asked for the last error message.

If you have any questions about mailroom machines please get in touch on 0118 982 0988